How does an expansion vessel work?

What might cause an expansion vessel to fail?

How often does an expansion vessel needs to be replaced?

All these questions and many more, are commonly raised by homeowners in London. So here is a comprehensive guide to answer all these queries involving expansion vessels in a combi boiler. The article will not only educate you on the information needed to understand the functioning, shortcomings, and maintenance of expansion vessels in a combi boiler but will also provide you with tips and tricks from professional Heating Engineer, Oliver Osmore at Maintracts Services, on handling your expansion vessel’s failure. Let’s begin!

What Is An Expansion Vessel?

As an indispensable component of most modern pressurised central heating systems, which includes combi boilers, system boilers, and some regular boilers, it helps regulate the optimal pressure in the boiler system. It prevents any increase in pressure beyond safe limits, which may cause serious accidents.

The primary function of the expansion vessel is to regulate the volume and pressure of the water and air in the heating system. This, in turn, prevents the pressure from exceeding the safety limits when the system contents expand whilst being heated by the boiler.

In short, the expansion vessel accommodates the increase or decrease in volume of the heating system when there is thermal contraction and expansion due to heating and cooling of water in the central heating system.

How Does An Expansion Vessel Work?

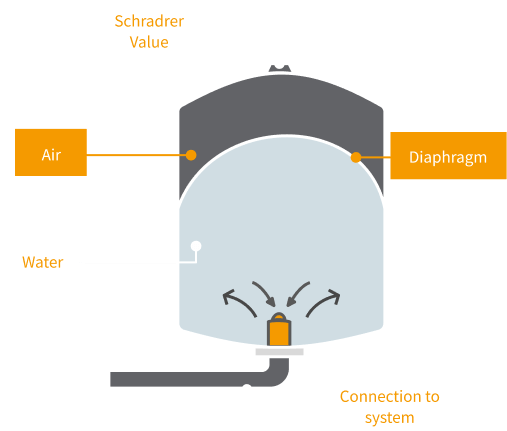

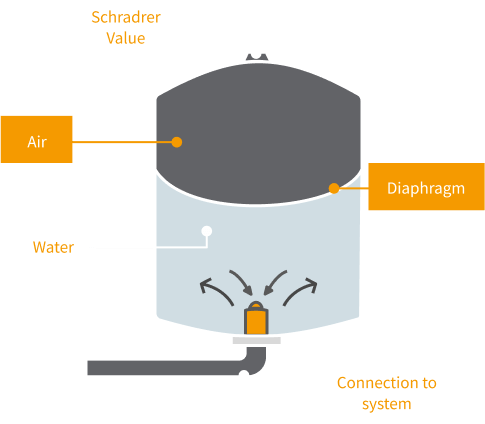

In a combination boiler, the expansion vessel is located inside the boiler casing, either towards the back or side of the casing. It is a metal vessel with either a diaphragm or a bladder inside. Whilst diaphragms and bladders serve the same purpose, they are distinctive designs:

The Diaphragm Expansion Vessel design boasts a flexible diaphragm that divides the vessel into two chambers – one for water and one for air (or inert gas). As water heats and expands, the diaphragm flexes to accommodate the growing volume, compressing the air/gas side to maintain the pressure in the system. Diaphragms are usually fixed in place.

Diaphragm expansion vessel design

Heating up / heating water

Cooling down / cooling water

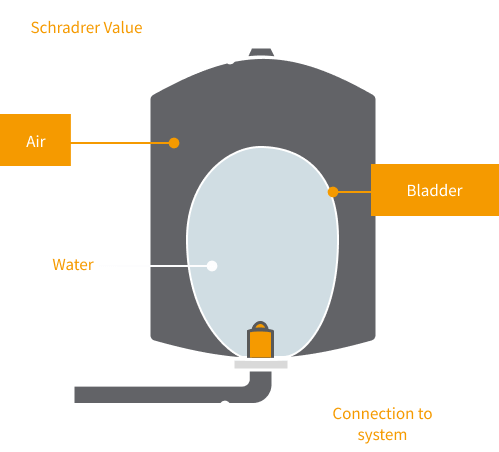

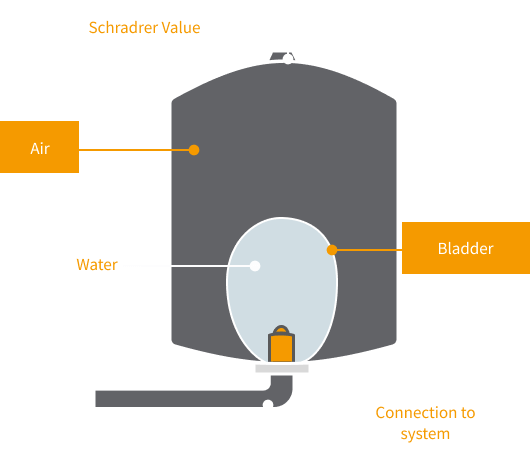

A Bladder (a flexible, balloon-like component) Expansion Vessel holds the water within it and expands and contracts within the vessel as the pressure changes. The bladder is surrounded by air/gas, which absorbs the pressure increase as water comes into the bladder. Bladders are easier to replace as they can be fully removed.

Bladder expansion vessel design

Boiler Heating up / heating water

Boiler cooling down / cooling water

The bladder-type expansion vessel design is the most common one among modern combi boiler systems. In this design, there is a bladder (a flexible, balloon-like component). On one side of the bladder the water is held, and the other side is filled with air, usually nitrogen. The tank has valves that help repressurise and depressurise the vessel over time.

Oliver Osmore at Maintracts Services explains:

“There is air/gas in between the bladder and outer layer of the vessel. When the heating system is switched on, the water in the system heats up and expands. Now, because it is a pressurised system, and the pressure is correctly set at 1.5 bar, the heated water expands in volume and exerts pressure on the bladder, which contracts in size to counter the increased pressure. Any excess air gets released through the system’s pressure relief valve.

The Schrader Valve is the component which pumps up the air in the expansion vessel as the water heats up and expands to compress the water and balance the systems pressure. The Schrader Valve can also release air if the vessel is over-pressurised when it is topped up.

When the boiler system cools down, the pressure decreases, and the bladder decreases in size, thus pushing the water back into the system from the expansion vessel.

Try visualising your expansion vessel as a football. A football holds air under pressure, and it needs to maintain the pressure to be fit for purpose. An expansion vessel works in the same way – it is designed to hold water under pressure, accommodating the expansion of water as it heats up in the central heating system. In a football, the internal pressure needs to be within a specific range for optimal performance. If it is too low or too high, the football’s performance will suffer. As we’ve learned, the expansion vessel is similar – it needs to maintain correct pressure to absorb the hot (expanded) water and prevent the boiler from becoming over pressurised.”

The following images shows an expansion vessel housed inside an Ariston Combi Boiler. Here, we removed the boiler to replace the split expansion vessel and pressure relief valve, ensuring everything is sealed and safe:

What Causes An Expansion Vessel To Fail?

- The diaphragm or bladder inside the expansion vessel is made of flexible membrane which contracts and expands often as the water volume increases when heated and gets smaller when cooling down. Over time, this stretchability tends to develop cracks on the membrane, and the functioning of the expansion vessel fails.

- The scale deposits of hard water on the vessel components are another reason the vessel stops functioning properly.

- The Schrader Valve leaking also prevents the expansion vessel from holding its charge.

The following images show an expansion vessel located outside of the boiler. Here, our heating engineer drained down, disconnected, and removed a leaking expansion vessel and magnetic filter and replaced with new to get the system back up and running efficiently:

What Should You Do If Your Expansion Vessel Is Not Working Efficiently Or Fails?

Here are some effective tips and tricks from the Managing Director of Maintracts Services in London to help you regulate the pressure in your combi boiler, even if the pressure tank fails:

- Temporary fixes to prevent over-pressurisation and pressure loss in your heating system.

During winter, when the heating system is frequently on, boiler pressure may rise excessively. This can cause the pressure relief valve to discharge water outside the system, leading to a drop in pressure and causing the boiler to shut down. As a result, you may find yourself repeatedly topping up the boiler manually. If this cycle persists, it’s advisable to have your expansion vessel serviced or replaced to restore proper function.

Important: For any boiler repairs in London, be sure to contact a qualified heating engineer or expert.

- If your expansion vessel is not working correctly, you can use a radiator as a temporary substitute. First you need to disconnect the radiator. Isolate the radiator by taking it off the wall and drain it. Then, put it back on the wall, connect it again, and open the valves. Now, you basically have a radiator that is full of air. It’s not going to provide you with any heat but will serve the same purpose as your expansion vessel. So, the entire air inside the radiator will do the same job as your expansion vessel. Now, when your heating system heats up, and the water in the system expands, the air in the radiator will contract to absorb the additional volume of the water and keep the heating system pressure regulated.

Please note: this is a short-term solution. For a permanent solution, contact a heating engineer to repair or replace the expansion vessel.

When Should The Expansion Vessel Be Replaced?

In the combination boiler, it’s typical to have the expansion vessel replaced once in its life cycle. A modern combination boiler has a life of 10-15 years, so you might need to replace its expansion vessel in a span of 8-12 years. The point to be noted is that even regular servicing of the boiler cannot ultimately prevent the vessel from failing. Regular servicing ensures that the vessel and the boiler perform correctly in their life cycle.

How Do You Recharge The Expansion Vessel Of A Combi Boiler?

You need to recharge your expansion vessel if you notice cold spots on the radiator, faulty boiler operations, faulty water pressure and noisy pump operations. In any of these scenarios, practice the below-mentioned steps:

1

If you need to repressurise or recharge the expansion vessel in a combi boiler, the best step is to connect with your most reliable boiler expert in London. However, here are a few tips and ideas on how to proceed with this task if you feel confident to try yourself.

2

Switch off your boiler.

3

Remove the fuse as an additional safety.

4

Ensure that the central heating side of the vessel isn’t pressurised.

5

Release any excess pressure first.

6

Check the pressure of the compressed air in the vessel using the recommended pressure in the boiler manual.

7

Recharge the pressure if low; using any air pump and attachment.

8

Check for any leaks in the Schrader Valve. To check this, put some liquid detergent over the valve; if bubbles form in this liquid detergent, the valve needs replacement.

9

Double-check all the fittings before starting the system.

“There is a data badge on the expansion vessel which will tell you what pressure it needs to be charged up to. So, when you pump up an expansion vessel or charge up an expansion vessel, you will have to do it every time. Pressure gets released from the heating system, so you have got to drain some water off the heating system, the pressure gets down to zero, and then you need to pump up your expansion vessel before repressurising the heating system.” – Oliver Osmore.

In conclusion, the expansion vessel is one of the most critical components of the central heating system. Therefore, you need to have a thorough knowledge of its functioning and its parts. Through this guide, we have made all efforts to ensure that you are well aware of the problems which might occur with your expansion vessel, the tips, and tricks to tackle minor issues and identify the situations when an expert for faulty boilers needs to be contacted.

Remember that your pressure tank needs annual servicing for foolproof functioning. This makes sure that the bladder inside the vessel is kept topped up with air to the appropriate pressure limit. Expansion vessels do gradually lose some pressure because of the whole cycle of the air being pumped up and released. The experts at Maintracts Services are fully qualified to deal with your modern or old-fashioned boilers and can offer a wealth of knowledge and experience. Our team can also help you with information on how a combi boiler works, boiler faults, and boiler servicing. All you need to do is call our team when needed.