Is your Worcester boiler indicating low boiler pressure?

Do not worry; not every solution requires the attendance of a certified engineer.

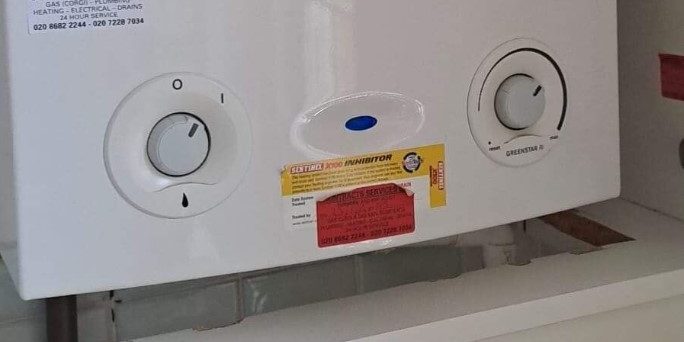

Knowing how to effectively top up Worcester boiler pressure will save you a time-consuming call out from a professional heating engineer. This guide will help you with all the essential steps needed to monitor the pressure gauge. You will also be guided on how to adjust your boiler pressure. Before we begin, make sure you turn off the boiler and allow it to cool.

Understanding Boiler Pressure

Boiler pressure determines the efficiency of your Worcester Bosch boiler. It refers to the pressure of the water within a closed heating system, measured in bars. It indicates the force at which the water is circulating through the rads, pipes, and the boiler itself.

This force is essentially to be maintained within a range, as it has a direct impact on the heating capability of your home. The ideal pressure can vary slightly depending on the model, but in general: When cold (when the system is at rest and not actively heating) the pressure range should fall between 1.0 and 1.5 bar. If the pressure drops below 1.0, you may need to top up the Worcester boiler pressure. However, it can also indicate a problem with the expansion vessel, so it is always good to check with a qualified heating engineer where the problem lies.

When the boiler is on and heating, the pressure will typically rise slightly, usually between 1.5 and 2 bar. A small rise when the system is hot is nothing to worry about as it is a result of the water expansion in the heating system. However, if it rises above 2.5 bar when hot, you will need to repressurise, or get it checked out.

Reasons Behind A Drop In Boiler Pressure

Trapped Air

Sometimes, air can get trapped within the system due to small leaks that allow air to enter, or gases produced by corrosion inside the rads. Trapped air can lead to cold spots on radiators and will reduce heating efficiency.

Leaks

If your Worcester boiler, its pipes, or radiators leak, it will lead to water escaping, which will eventually cause pressure leaks. This is a serious concern and needs to be addressed promptly.

No Air In The Expansion Vessel

The expansion vessel is an important component of the boiler as it balances the pressure within the system by preventing any excess build-up. If the expansion vessel of the boiler has no air in it, it leads to fluctuations in pressure and can eventually damage the boiler. As a solution, it is necessary to top up the boiler pressure.

Ways To Increase Pressure On A Worcester Boiler

Bleeding Your Radiators

Sometimes you will be able to repressurise your system by bleeding your radiators:

- To increase the boiler pressure using the bleeding radiator method, you first need to turn off the heating system.

- Use a radiator key to open the bleed valve positioned at the top of each radiator.

- Once all air has escaped and water starts to flow steadily, close the valve. The air pressure should now be between 1-1.5 bar.

- Regular bleeding is recommended for optimal pressure.

View our detailed guide on how to bleed a radiator for more information.

If after bleeding your radiator, your boiler pressure is still reading low, try the following:

Topping Up Boiler Pressure

- Turn off the boiler completely and allow it to cool to avoid risk of injury.

- Check the pressure gauge reading. The pressure gauge is usually found on the front of the boiler, and remember, when it is cold it should read between 1.0 and 1.5 bar. If you’re trying to top it up, it will be reading below 1.0 bar.

- Locate the filling loop which is usually identifiable as a silver, flexible hose located underneath the boiler with a valve attached to each end.

- Attach the filling key (if applicable). Some Worcester models, require a filling key to open the valves attached to the filling loop. If your boiler has a keyed filling loop, insert the key into the slot and turn to unlock the filling loop. Filling keys are available from plumbing merchants if you can’t find yours.

- Open both valves on the filling loop. Do this slowly. You should start to hear the water flowing through the system.

- If you have a keyless filling link where no separate key is required to open the valve and add water, you can simply remove the bottom boiler cover and locate the blue lever or dial, which is normally on the right-hand side. Pull the lever down; you will hear the sound of water passing through.

- Monitor the pressure gauge closely as you open the valves because as the water flows in, the pressure on the gauge will begin to rise. Allow the pressure to reach the required level (between 1.0 and 1.5 bar).

- Close both valves. Once the pressure is within the ideal range, close both valves with the filling key so the valves are backed to their locked position and the water flow has stopped. Remove the key and keep it somewhere safe for future use.

- Check for leaks around the filling loop and surrounding area.

- Turn the boiler back on once you are certain there are no leaks, and check it is working correctly.

If your boiler pressure still doesn’t rise after following the above steps, there will likely to be another culprit causing the problem, such as a leak or problem with the expansion vessel. These are definitely jobs that should be resolved by a certified plumber or heating engineer.

Knowing the reasons behind boiler pressure fluctuations and knowing how to identify and resolve them will make you more confident in handling boiler pressure concerns. If you own a Worcester boiler (or any boiler for that matter), it is important to ensure it receives an annual boiler service to ensure it is working as efficiently as it should be and to pick up on any small issues like pressure fluctuations, before they become bigger, costlier ones. Whether you want to book in a boiler service, need a boiler repair, you've noticed a leak, or you are just not feeling confident enough to repressurise your boiler yourself, please reach out to our expert, certified team at Maintracts Services who would love to help.